Yet Another Breakthrough Innovation in Metal 3D Printing

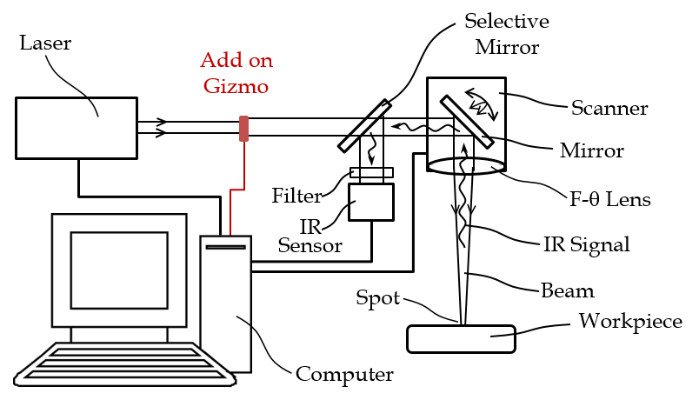

Every Developer of Additive Manufacturing machines is chasing three key discriminating parameters – speed, quality, and size; generally hard to accomplish all at the same time. One of my clients recently had a conceptual breakthrough, where a small optical gizmo retrofit will enable improved micro-structure (means better Quality) at faster speeds.

Standard laser beam technology provides non-uniform thermal profiles even for straight scanning paths at low velocities, making their application less than ideal for product uniformity, or for sensitive applications like production of single-crystal super alloy parts.

Advanced optics and matching simulation technology provide precision heating introduction, which assures uniform consolidation while reducing over temp. This, and the ability to regulate the cooling rate permits faster processing speeds.

This is yet another innovation in a rapidly evolving (disrupting) technology, addressing the need for a fast, accurate, and reliable way to control the quality of additively manufactured metal parts.

In the spirit of LinkedIn, I would be happy to link up established equipment manufacturers with the inventor.