Purpose and Pursuit of NDE 4.0

What is NDE 4.0 ?

(NDE is a short form for Non-Destructive Evaluation)

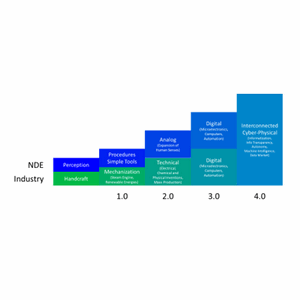

NDE 1.0 was human sensory (visual, hearing, touch, smell) based inspection with some schedule and evaluation criterion. NDE 2.0 is when analog instruments and methods began to provide amplification and even ability to look beyond line of sight, or hidden within material below the surface. NDE 3.0 is marked with advent of digital technologies for signal processing and visualization. NDE 4.0 can be defined as a Cyber-physical Non-Destructive Evaluation System; a confluence of industry 4.0 technologies with traditional NDE physical methods.

A Depot maintenance scenario projected by Deloitte throws open some very interesting opportunities. Imagine that the depot begins ‘all and only’ necessary activities before the asset arrives; Augmented reality guides the crew activities on the asset on arrival; Advanced scheduling had already orchestrated acquisition of spares/repairs; Intelligent workflow has optimized the downtime; Components are tagged with real time performance data; Robots begin performing inspections with better POD; AI looks at the correlations with data from other assets and creates prescriptive analytics; 3D Printing is brought in to help with missing spares and special tools; and the asset is all set to go back to service – safer, faster, and cheaper. All of these technologies work like an orchestra serving the purpose.

Why NDE 4.0?

The purpose of NDE 4.0 can be defined as “Safety 5.0 – To concurrently Enhance Safety and bring Economic Value to stakeholders”.

To begin with, most digital systems offer a clear advantage over traditional system in terms of accuracy and speed. However, a significant contribution of Cyber-Physical NDE system (NDE 4.0) stems from the better control or total elimination of human factors. This leads to a more reliable inspection system, i.e. better Probability of Detection (POD) and a more consistent POD from inspection to inspection. This improved and dependable anomaly detection provides enhanced safety, and enables optimization of inspection programs reducing life time operating cost of an asset. The structured management of life time digital data, like a digital twin, opens up additional economic opportunity to asset manufactures and operators. Therefore NDE 4.0 provides an opportunity to advance all three – quality(safety), speed, and cost, as compared to the traditional perspective that you can only choose two out of the three. That is why it is called the next revolution.

Challenges with NDE 4.0

NDE 4.0 has its challenges, pretty much from all aspects, given the nature of multiple simultaneous disruptions. Visible challenges are related to technology, talent, and processes. The intangible ones include culture change and fresh leadership mindset. And on top of these, we need to prepare for those completely unknown at this time, associated with a changing role of human interaction with cyber-physical systems. Let’s look at a few top ones.

First, the technology standardization around data connectivity, exchange, security, analytics, synthesis, interpretation are still evolving. In fact, some argue that continuous change is the new normal. The underlying technology may just always stay in a state of continuous flux.

Second, the organizations need a whole new skill set. Skills around Information and Communication Technologies (ICT not just IT), co-working with intelligent systems, (desktop as well as industrial Cobots), and more importantly willingness to accept that what you know today will likely be obsolete before you can establish yourself as an expert. The need and speed for learning in the 4th revolution is an order of magnitude larger than the previous revolution.

Third, the companies need a slightly different leadership mindset. Competitive forces are unpredictable. Technology is rapidly changing. Communication needs to be real time. This means the hierarchical organization structures are detrimental to adaption of Industry 4.0 and leaders need to free up the decision-making process. Peripheral vision, leadership agility, transparency, and connectivity is absolutely important to thrive in this era of Volatility, Uncertainty, Complexity and Ambiguity (VUCA)

Fourth, once the leadership prepares itself for the transformation, they need to change the culture. Basic principles of physics come to play here. Adaption of new systems requires them to address fear of failure to deliver on expectation (inertia) and resistance to change (friction). Leadership ought to define clear value proposition (lubrication), sponsor learning and technology projects (energy) to sustain transformation (momentum).

Finally, the traditional business culture seeks a traditional return on investment (ROI) analysis before investing. While working through the revolution, the traditional analysis does not work. You need to account for the cost of not investing, which at times could as high as bankruptcy.

NDE 4.0 Community Pursuit

Purposeful pursuit of NDE 4.0 needs to be a team sport. The NDT thought leadership has come together to create knowledge platforms for guidance on this topic.

DGZfP and ASNT have formed committees to align the communities. The upcoming WCNDT in Seoul will likely see an international committee on NDE 4.0. In 2021, DGZfP is organizing the first International Conference on NDE 4.0 in Munich.

Author Ripi Singh is chairperson for ASNT Committee on NDE 4.0. Over 25 experts have joined the committee and offered to help on various aspects – create a knowledge exchange platform/forum, endorse existing standards, Ethics, and build a resource directory for international use.

Further more…

Request a 2-day workshop on NDE 4.0 at your facility, in partnership with Johannes Vrana and Hellier NDT.

Watch a recent conversation on the topic with Bruce Breeden recorded by Floodlight Software.

To support ASNT committee on NDE 4.0, contact us here.